- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

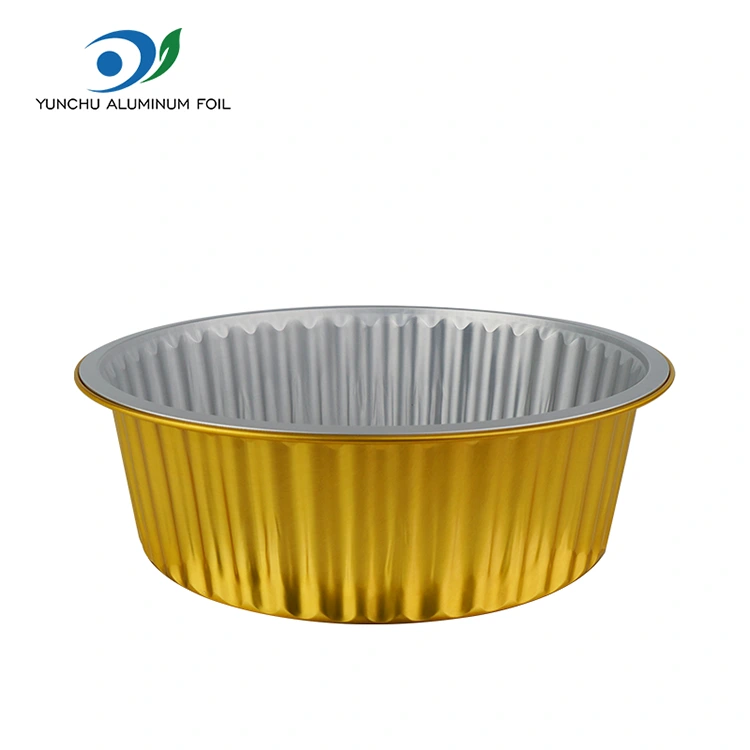

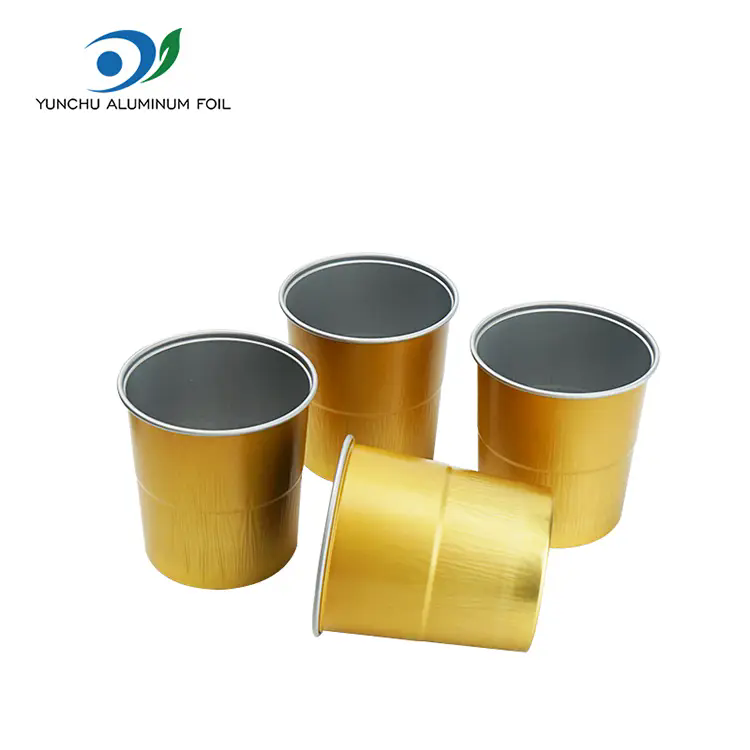

Aluminum Drink Cup

Company Profile

Yunchu is a leading China Aluminum Drink Cup manufacturer. Our product range includes Aluminum Cups, Aluminum Foil Containers, Airline Meal Aluminum Foil Containers, etc. Our Newest Disposable Recyclable Cold-Drink Aluminum Cups series products include 20oz disposable aluminum cup simple aluminum drink cup, 16oz disposable aluminum foil cup custom aluminum drink cup, etc.

As an original factory established in 2004, we have a complete and efficient modern intelligent production line with over twenty years of production experience. We adhere to independent design and research and development, ensuring product quality while offering excellent cost advantages. Our production area is vast, and all orders are completed internally in an integrated manner, from raw materials to finished products, achieving full internal control and strict quality management throughout the process. We have a strong R&D technical team, experienced process engineers, and a standardized production management system. Each production process is transparent and open, and we welcome customers to visit our factory at any time.

Currently, our Disposable Aluminum Cups have been exported to over 50 countries and regions around the world. All products have passed ISO 9001 quality management system and SGS food-grade safety and other international standards certifications. We look forward to becoming your long-term and reliable partner in the global market.

About our Aluminum Drink Cup

YUNCHU newest Disposable Aluminum Cups are specifically designed for parties and outdoor gatherings. The cups are made of BPA-free, food-grade aluminum foil material, ensuring safety and odor-free performance for various hot and cold beverages. Key advantages include: combining environmental friendliness with durability, using 100% recyclable aluminum, compatibility with dishwasher cleaning, reusability, lightweight yet sturdy construction, and excellent ice retention. The aluminum's superior thermal conductivity quickly locks in the refreshing chill of beverages, making it an ideal choice for brand party supplies and social occasions.

Product Advantages

●Our Reusable Aluminum Party Cups are made from high-purity food-grade virgin aluminum foil, ensuring safe and stable material with no off-flavors or harmful substance leaching, providing reliable assurance for food safety.

●This aluminum container boasts excellent thermal conductivity, quickly cooling hot beverages and effectively locking in an icy sensation. Whether for ice-cold wine, cold brew coffee, or carbonated drinks like cola, it helps preserve a delightful taste. For hot beverages, we recommend using it with a cup sleeve

●Meanwhile, aluminum foil is lightweight yet sturdy, with aluminum cups made from it having a thickness of ≤2mm, ensuring a comfortable and lightweight grip while significantly reducing transportation costs. Additionally, it boasts excellent resistance to pressure and deformation, guaranteeing the integrity of food items during transportation and stacking.

●All cups undergo rigorous quality inspection and factory testing, offering services ranging from standard sizes to fully customized options. Exclusive patterns or brand logos can be printed on the cup body, creating a unique appearance that enhances brand value and better exposure for diverse customer needs.

●Unlike plastic and paper products, this aluminum cup is eco-friendly and durable, supporting sustainable use. Made from 100% recyclable aluminum, this Dishwasher Safe Aluminum Cup enables infinite recycling, facilitates easy and efficient repeated cleaning, resists deformation and damage, and boasts exceptional durability.

●Our products have all passed ISO 9001 and SGS food grade safety certification, meeting the import and demand standards of the international mainstream market. Currently, it has been exported to over 50 countries and regions worldwide, serving numerous well-known brands. To provide you with compliant and reliable product support.

Full Production Process

Material storage

All the raw materials of our Aluminum Drinking Cup are stored in a dedicated warehouse with constant temperature and humidity. The core raw material - food grade aluminum foil rolls, is purchased from internationally renowned suppliers, and each batch comes with a material safety report to ensure food safety and stable quality from the source.

⏬

Mold room

Our company has over 1000 sets of professional mold warehouses. The mold engineer will call or customize high-precision molds from the library according to the order requirements, and use the CNC machining center for precision maintenance and debugging, to ensure that the final product size is accurate, the edge is smooth, and perfect molding is achieved.

⏬

Production

The aluminum foil roll completes the entire process from feeding, cup punching, edge rolling, to forming on the fully automatic high-speed stamping production line. More than 20 automated production lines ensure large-scale and efficient production, while using precision stamping equipment to ensure uniform wall thickness, consistent structure, and no defects for each cup body.

⏬

Strict quality control and test

The production line will automatically conduct random inspections at a preset frequency. The quality inspector conducts multidimensional testing on the samples in an independent quality inspection center, including dimensional accuracy, sealing (leak proof), compressive strength, and simulated high and low temperature resistance testing to ensure that the performance of each batch of products meets ISO and customer standards.

⏬

Product sample

For new designs or customized orders, samples will be made before production and sent to customers for physical confirmation. This step ensures that the appearance, size, and functionality (such as compatibility with the cup lid) fully meet customer expectations and is a key step in OEM/ODM customization services.

⏬

Product packaging

Qualified products that have passed the test enter the automated packaging line. The system automatically counts and stacks according to the preset quantity, and loads it into inner bags or cardboard boxes. The packaging process is clean and efficient, and customized printing packaging materials can be used to enhance brand image and facilitate logistics identification

⏬

Finished Goods in Warehouse

The packaged products are sent to the finished product warehouse for intelligent storage management based on model and batch. The warehouse environment is clean and dry to ensure the storage quality of products before delivery. The ERP system synchronizes inventory in real-time to ensure that orders can be quickly and accurately prepared for shipment.

⏬

Load into container

According to the shipping plan, finished boxes are loaded into containers by a professional team according to an optimized plan to ensure maximum utilization of transportation space, and necessary measures are taken to prevent compression or displacement during transportation. Each container of goods comes with a complete factory inspection report and compliance documents to ensure smooth customs clearance.

Yunchu is a Aluminum Drink Cup manufacturer and supplier in China, we have own factory. You may need some high quality and customized products to meet the actual needs of your region.